Rejoindre TMAX, devenir agent!

Rejoindre TMAX, devenir agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Numéro d\'article.:

TMAX300HHPaiement:

L/C, T/T, Western Union, Credit Cards, PaypalOrigine du produit:

ChinaPort d\'expédition:

Xiamen PortDélai de mise en œuvre:

5 Dayscertificat :

CE, IOS, ROHS, SGS, UL Certificategarantie :

Two years limited warranty with lifetime technical support

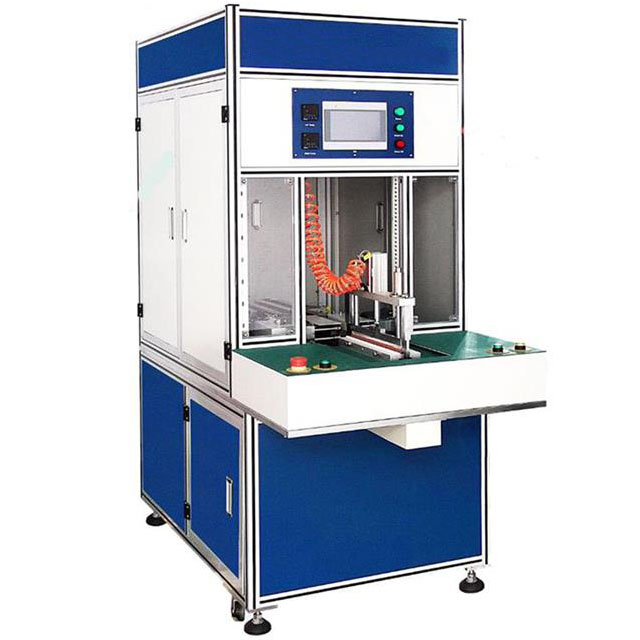

Présentation

TMAX300HH est une machine trois-en-un qui fournit un flux de travail continu pour la coupe des bords, le pliage et le repassage de très grandes pochettes cellulaires sans main d'œuvre dédiée. Ce processus est largement utilisé dans les étapes finales de la chaîne de production pilote de batteries en poche pour garantir un bord du boîtier lisse, propre et bien rangé.

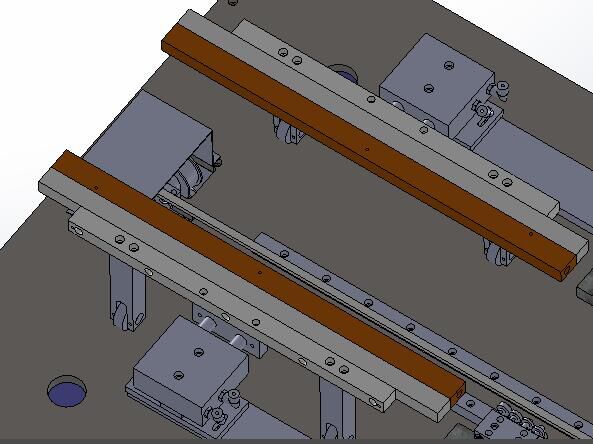

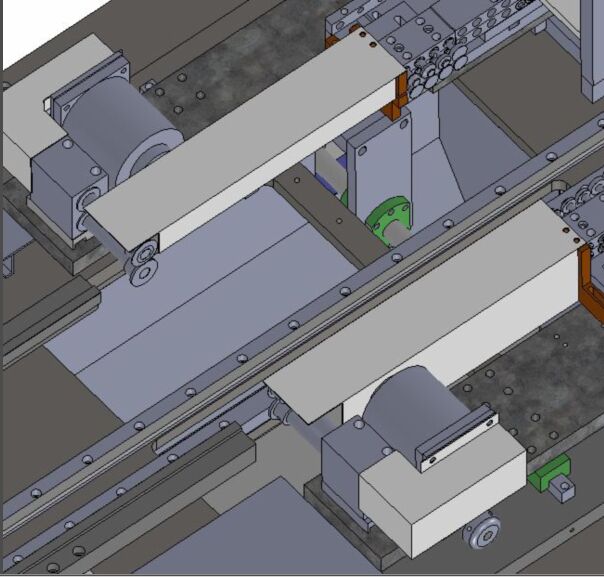

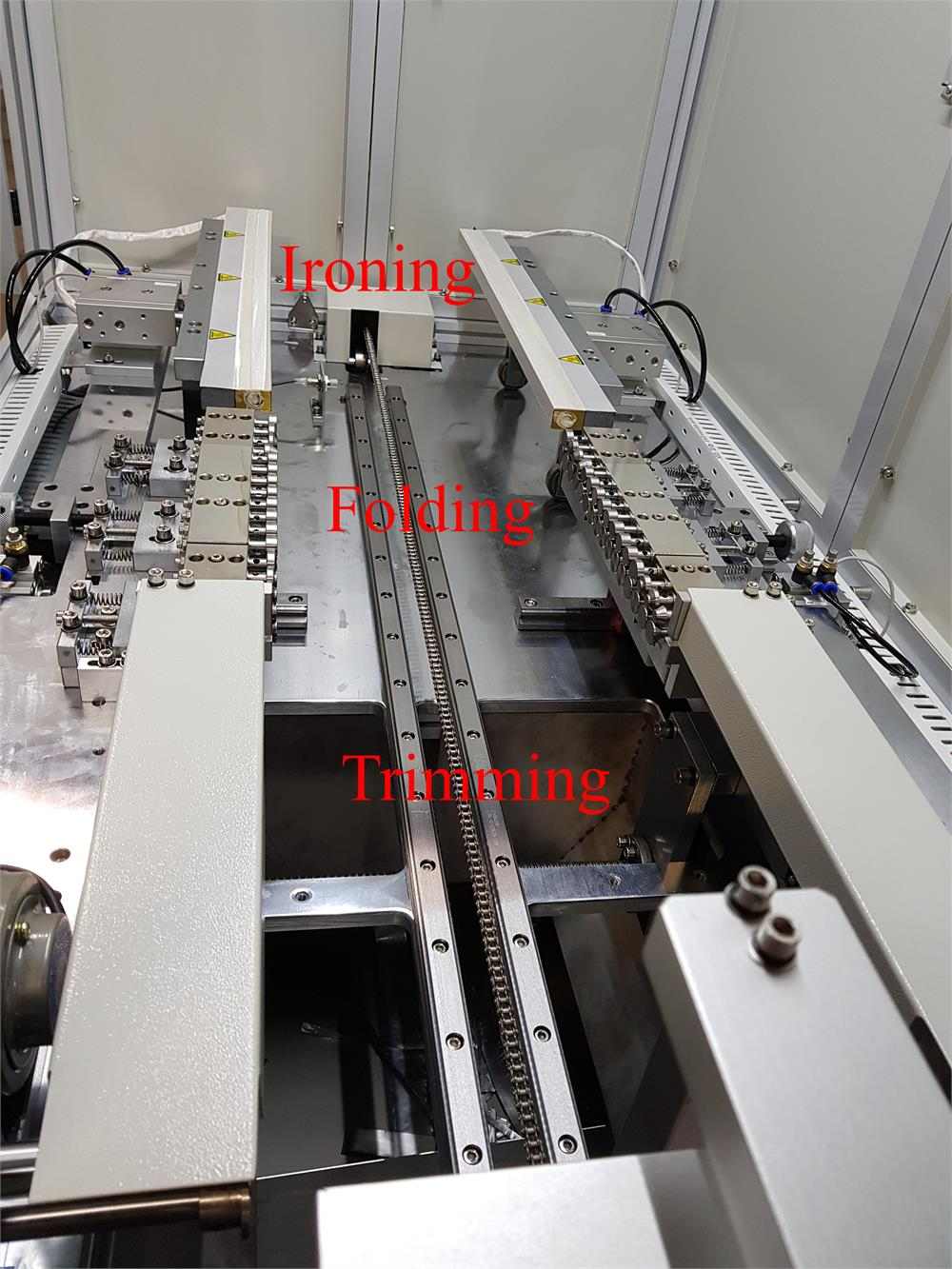

Module de repassage

Découpage Module

Pliable Module

Max. Consommation d'énergie

2,5KW

Tension de fonctionnement

208-240 VCA, monophasé

Pression de l'air comprimé

· 0,7 - 0,8 MPa (chaque course consommera 0,09 L d'air)

· Remarque : le compresseur d'air n'est pas inclus.

Informations sur la taille (repassage des bords, coupe et largeur/longueur du pliage)

· Longueur de cellule : 10 ~ 580 mm

· Largeur de cellule : 10 ~ 240 mm

· Épaisseur des cellules : 2 ~ 12 mm

Informations sur la température

Température de repassage : 0-250â réglable

Temps de séjour

0-99 secondes réglables

Productivité

160 ~ 220 pièces/h (durée de vie prévue de la lame de coupe ~ 1 million de fois)

Précision de coupe

+/-0,1mm

Modes de travail

· Flux de travail continu pour la coupe des bords, le pliage et le repassage des étuis à cellules extra larges (le chargement manuel des étuis est nécessaire)

· Grille coulissante linéaire pour une manipulation aisée des modules de coupe, de pliage et de repassage.

Comment utiliser

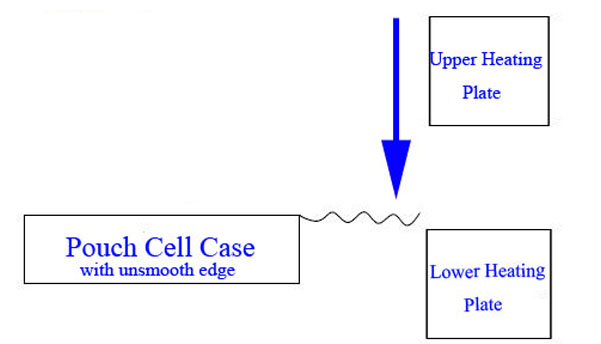

Lorsque la cellule de poche est fabriquée, un excès de bordure inégal est attendu. Afin de créer une cellule propre et bien rangée avec des bords lisses, tout comme les piles de poche commerciales, veuillez suivre les étapes ci-dessous :

Dimensions du produit

2000X 850 X 1800 mm

Poids net

360Kg

Garantie

Garantie limitée de deux ans avec assistance à vie.

Étape 1. Le module de coupe coupera la zone excédentaire du bord du boîtier, ne laissant que la taille appropriée pour le pliage et le repassage du bord

Étape 2. Le module de repassage va lisser le bord avant le pliage

Étape 3. Le module de pliage pliera partiellement le bord

Étape 4. Le repassage Le module lissera à nouveau la section pliée, puis repassera la section la plus longue contre les côtés de la coque. Maintenant, une cellule propre et bien rangée est terminée.

1 emballage standard exporté : protection anticollision interne, emballage de boîte en bois d'exportation externe.

2 Expédition par express, par avion, par mer selon les exigences des clients pour trouver le moyen le plus approprié.

3 Responsable des dommages pendant le processus d'expédition, changera gratuitement la pièce endommagée pour vous.

Précédent :

Machine semi-automatique de thermoscellage de batterie à quatre stations pour l'emballage de batteries au lithium de cellules de pocheSuivant :

Machine de pliage de bord pour éliminer les bords redondants des deux côtés de la cellule de pocheCatégories

Nouveaux produits

boîte à gants sous vide en acier inoxydable h2o & O2 système de purification En savoir plus

Broyeur à boulets planétaire pour le broyage de poudre En savoir plus

Lab 12t Presse hydraulique manuelle avec une jauge de pression numérique optionnelle couramment utilisée dans les laboratoires infrarouges En savoir plus

© Droit d\'auteur: 2026 Xiamen Tmax Battery Equipments Limited Tous droits réservés.

IPv6 réseau pris en charge