Rejoindre TMAX, devenir agent!

Rejoindre TMAX, devenir agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Numéro d\'article.:

TMAX-TMJ150Paiement:

L/C, T/T, Western Union, Credit Cards, PaypalOrigine du produit:

ChinaPort d\'expédition:

Xiamen PortDélai de mise en œuvre:

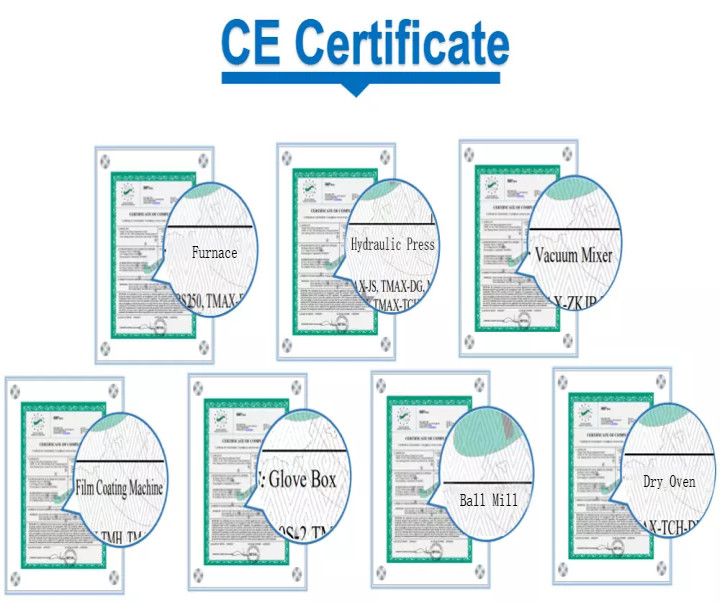

5 Dayscertificat :

CE, IOS, ROHS, SGS, UL Certificategarantie :

Two years limited warranty with lifetime technical support

Demande

Il convient à la protection automatique de la batterie MYLAR après le scellement supérieur et latéral de la cellule au lithium pour éviter de rayer la surface de la cellule pendant le processus d'étirage.

Principe

Placez manuellement la cellule de batterie à la verticale dans la rainure du guide d'alimentation, poussez la cellule de batterie vers le bloc de positionnement avant et envoyez la cellule de batterie positionnée vers le rouleau en caoutchouc de tournage pour terminer le tournage, puis envoyez-la par la bande transporteuse (décharge ) Lieu de recyclage (cet équipement réalise une seule personne et une seule machine)

Paramètres de base

|

Alimentation |

AC220V/50Hz, puissance : 1,5KW (préparé par le client) |

|

Air comprimé |

â¥0,6 MPa 10L/min (préparé par le client) |

|

Poids |

Environ 500kg |

|

Dimensions |

(L*L*H) 1400*1200*1700 mm |

|

Couleur |

Gris chaud international 1C |

Paramètres techniques

|

Spécifications applicables |

W : 30-100 mm (sans airbag) ; H : 50-150 mm, T : 3-12 mm |

|

Peut être ajusté en fonction de différents types de batteries, plage de réglage de la largeur de la batterie |

30-100 mm (sans airbag) |

|

Paramètre d'entrée |

Le diamètre extérieur maximum du film protecteur est de 300 mm et le diamètre intérieur d'installation est de 78 mm |

|

Bâton rouleau MYLAR longueur efficace |

150mm |

|

Précision |

Une fois la cellule de batterie collée avec le film protecteur, la précision du sens de la longueur de la cellule de batterie est de ± 0,5 mm et la précision du sens de la largeur est de ± 0,5 mm |

|

Sortie |

900-1200 pièces/h |

1 emballage standard exporté : protection anticollision interne, emballage de boîte en bois d'exportation externe.

2 Expédition par express, par avion, par mer selon les exigences des clients pour trouver le moyen le plus approprié.

3 Responsable des dommages pendant le processus d'expédition, changera gratuitement la pièce endommagée pour vous.

Précédent :

Machine de cachetage de deux postes de travail pour le cachetage supérieur et latéral de cellules de pocheSuivant :

Machine de revêtement d'électrode automatique, système de revêtement pilote polyvalent roll-to-rollCatégories

Nouveaux produits

boîte à gants sous vide en acier inoxydable h2o & O2 système de purification En savoir plus

Broyeur à boulets planétaire pour le broyage de poudre En savoir plus

Lab 12t Presse hydraulique manuelle avec une jauge de pression numérique optionnelle couramment utilisée dans les laboratoires infrarouges En savoir plus

© Droit d\'auteur: 2026 Xiamen Tmax Battery Equipments Limited Tous droits réservés.

IPv6 réseau pris en charge