Rejoindre TMAX, devenir agent!

Rejoindre TMAX, devenir agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Numéro d\'article.:

TMAX-ZL-LB650Paiement:

L/C, T/T, Western Union, Credit Cards, PaypalPort d\'expédition:

Xiamen PortDélai de mise en œuvre:

5 Dayscertificat :

CE, IOS, ROHS, SGS, UL Certificategarantie :

Two years limited warranty with lifetime technical support

Machine de revêtement par transfert d'électrodes rouleau à rouleau pour la fabrication de batteries au lithium

La coucheuse de la série ZL-LB est un équipement de revêtement professionnel pour batterie au lithium.

1.Il convient au processus de revêtement de systèmes à boues tels que le phosphate de fer au lithium huileux ou à base d'eau, l'acide cobaltique au lithium huileux, le ternaire, le manganate de lithium, le manganate de nickel-cobalt-lithium, le graphite de carbone négatif huileux ou à base d'eau, titanate de lithium, etc. ;

2. La précision du contrôle de tension peut atteindre le niveau ± 1N en utilisant le système de contrôle de tension en boucle fermée PID entièrement automatique ;

3.Les pièces standard importées telles que le système de contrôle PLC OMRON et le servomoteur de haute précision sont utilisées pour garantir la cohérence et la stabilité ultra-élevées des produits revêtus en termes de densité de surface et de taille. La proportion de pièces standard importées atteint 85 %.

Spécifications

|

Matériaux appropriés |

Phosphate de fer et de lithium à base d'huile ou d'eau, cobalt de lithium, manganate de lithium, ternaire, manganate de lithium-nickel-cobalt, titanate de lithium, graphite de carbone et autres systèmes |

|

Paramètres de fonctionnement du substrat |

Feuille d'aluminium : Épaisseur : 10-30 um ; Largeur : 200-620 mm ; Diamètre de la bobine : max. 500 mm ; Poids : maximum 500 kg ;

Feuille de cuivre : Tépaisseur : 6-30 um ; Largeur : 200-620 mm ; Diamètre de la bobine : max.500 mm ; Poids : max. 500 kg ; |

|

Largeur de conception du rouleauer |

650 mm |

|

Efficace largeur de revêtement |

200~580mm |

|

Vitesse de fonctionnement mécanique de l'équipement |

12 m/min |

|

CouvercleVitesse de navigation |

0,5-8 m/min |

|

matériau approprié viscosité |

2 000 ~ 12 000 cps |

|

Plage d'épaisseur sèche du revêtement simple face |

50-150μm |

|

Durée minimale intermittente |

5mm |

|

Longueur minimale de revêtement en plusieurs étapes |

20mm |

|

Propriétés du solvant |

Solvant huileux : NMP (s.g=1,033, b.p=204â) Solvant aqueux : H2O/NMP (s.g=1.000,b.p=100â) |

|

Contenu solide approprié |

Anode : Sï¼C. 60%±20% Cathode : Sï¼C. 50 % ± 10 % (système PVDF ) Sï¼C. 50%±5%ï¼SBR systèmeï¼ |

|

Densité relative |

Anode : 1,5–2,59/cm2 Cathode : 1ï½1,89/cm2 |

|

Méthode de revêtement |

Double couche double face Revêtement par transfert intermittent à distance inégale en 3 étapes / suivi automatique sur la deuxième face / revêtement par transfert continu |

|

Mode de changement de rouleau |

manuel |

|

Sens de marche du matériau de base |

Enduction avant, opération de feuille vide avant et arrière du substrat |

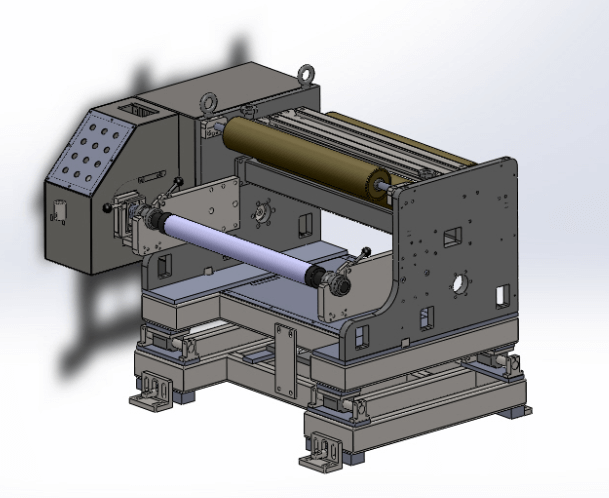

Structure de la machine

1. Mécanisme de déroulement (rembobinage manuel à un seul bras)

La partie déroulement a principalement trois fonctions : déroulement actif, correction automatique en temps réel et contrôle automatique de la tension ;

Le déroulement actif est alimenté par le moteur via la poulie synchrone, et la vitesse de déroulement est déterminée en fonction du changement en temps réel de la tension et de la vitesse de revêtement. L'ensemble du processus se déroule automatiquement pour garantir une parfaite adéquation entre la vitesse de déroulement et la vitesse de revêtement. Il évite les grandes fluctuations de tension provoquées par la puissance de sortie non linéaire de la poudre magnétique qui ne peut pas contrôler la vitesse de déroulement en temps réel et activement lorsque la poudre magnétique conventionnelle se déroule passivement, ce qui affecte la vitesse de revêtement.

|

Structure d'installation du rouleau |

Installation de plaque verticale intégrale (épaisseur 30 mm) |

|

Traitement de surface des rouleaux |

Traitement d'oxydation de surface du rouleau d'aluminium , la dureté de la surface est HRC65, le dépassement du rouleau est de ⤠20 μ m, la rugosité de la surface est de Ra0,8, le parallélisme est de ⤠0,1 mm ; |

|

Système de contrôle de tension |

Tension constante de contrôle en boucle fermée PID entièrement automatique ; plage de tension de déroulement : 0~50 N ; précision du contrôle de tension ± 1N; |

|

Méthode de correction |

Contrôle EPC automatique, course 120 mm |

|

Méthode d'enroulement |

Déroulage vers le haut et vers le bas La bobine est fixée avec un arbre gonflable de 3 pouces et un arbre gonflable Mèche gonflable simple de déroulement, support double face Plateforme d'épissure manuelle, mode double barre de compression |

|

Substrat sens de déplacement |

avant et en arrière |

|

Vitesse de déplacement du substrat |

12 m/min |

|

Diamètre maximum de déroulement |

Ф500 mm |

|

Capacité portante maximale de l'arbre gonflable |

500Kg |

|

Nombre d'arbres gonflables déroulants |

1 |

|

Système de contrôle |

Réglez le bouton de fonctionnement de la fonction, qui peut compléter l'opération d'extension de bande, de pause, d'arrêt d'urgence, d'avant et d'arrière, d'alignement gauche et droit, etc. |

|

Vitesse de déroulement |

La vitesse de déroulement est contrôlée par PLC en fonction de la vitesse de revêtement réglée et des données de changement de tension en temps réel ; la puissance de déroulement est fournie par un moteur AC + un réducteur à turbine ; |

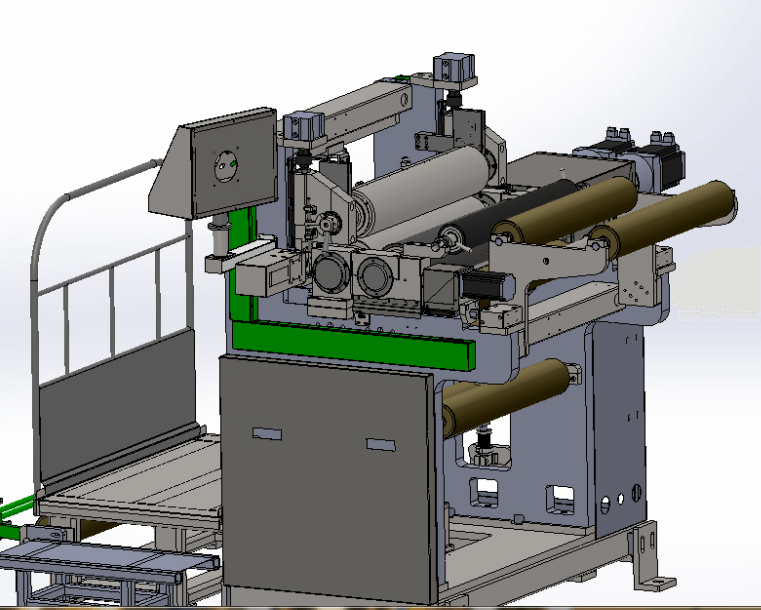

2.Mécanisme de revêtement

La tête de la machine est principalement composée d'un mécanisme de racleur, d'un mécanisme à rouleaux en acier, d'un mécanisme à rouleaux en caoutchouc et d'un entraînement à rouleaux en caoutchouc.

· Le mécanisme du grattoir entraîne la tige filetée de haute précision vers le bloc incliné via le réducteur à vis sans fin, et passe au mouvement de haut en bas du grattoir via le mouvement horizontal du bloc incliné et du bloc incliné, ce qui rend le la précision du réglage est plus précise, plus facile à contrôler et réduit considérablement le jeu inverse.

·Le mécanisme à rouleaux en acier est relié à la tige en acier via l'accouplement à double membrane via le servomoteur. Le roulement à rouleaux en acier adopte un roulement importé de haute précision, qui garantit un faux-rond inférieur à 1,5 um après l'installation grâce à une méthode d'installation unique.

· Comparé au mécanisme à rouleaux en caoutchouc traditionnel, le moteur d'entraînement est fixe et la connexion souple de l'accouplement à double membrane évite l'influence des vibrations du moteur sur le revêtement, assure la précision du revêtement, évite le moteur et le caoutchouc. le rouleau se déplaçant d'avant en arrière ensemble, prolonge la durée de vie du moteur et réduit l'inertie du rouleau en caoutchouc pendant le revêtement.

·Le mécanisme d'entraînement du rouleau en caoutchouc relie le moteur et le rouleau en caoutchouc via la tige à vis et convertit le mouvement de rotation du moteur en mouvement avant et arrière du rouleau en caoutchouc. Le siège du rouleau en caoutchouc et le moteur sont installés sur le bloc coulissant mobile, avec une réponse rapide et une haute précision.

|

Structure d'installation |

Structure en plaques verticales globales de 50 mm d'épaisseur, poids total de 1 tonne |

|

Moteur d'entraînement principal |

Servomoteur (750W) |

|

Moteur de poussée intermittente |

Servomoteur (750W) |

|

Traitement de surface des rouleaux |

La surface du rouleau d'aluminium est oxydée, la dureté de la surface est HRC65, le manque de rouleau est ⤠20 μ m, la rugosité de la surface est Ra0,8, le parallélisme est ⤠0,1 mm ; |

|

Réducteur |

100:1 avec réducteur 750W |

|

Structure du grattoir |

Grattoir virgule double face, galvanisé, diamètre extérieur Φ 128 mm, |

|

Contrôle de rotation de l'angle de la lame |

Rotation de la poignée |

|

Rouleau de revêtement (rouleau en acier) |

La surface est plaquée de chrome dur importé, d'un diamètre de 128 mm ; |

|

Tension |

Tension constante de contrôle en boucle fermée PID entièrement automatique, plage de tension 0 ~ 50N, précision du contrôle de tension ± 1n |

|

Rouleau arrière |

160 mm de diamètre, EPDM importé pour le pain de surface, broyage fin pour la surface du rouleau |

|

Mélange en cuvette |

Mouvement droit du vérin sans tige, vitesse réglable |

|

Déflecteur |

Matériau Saigang, scellé avec de la mousse de polystyrène, équipé d'un moule à couteau spécial |

|

Réglage intermittent de la hauteur de la lame |

Réglage du servomoteur : définissez la taille intermittente du grattoir et du rouleau en acier sur l'écran tactile, avec la taille de réglage minimale de 0,1 um |

|

Position de la tête autonome |

Installation et fonctionnement avant séchage |

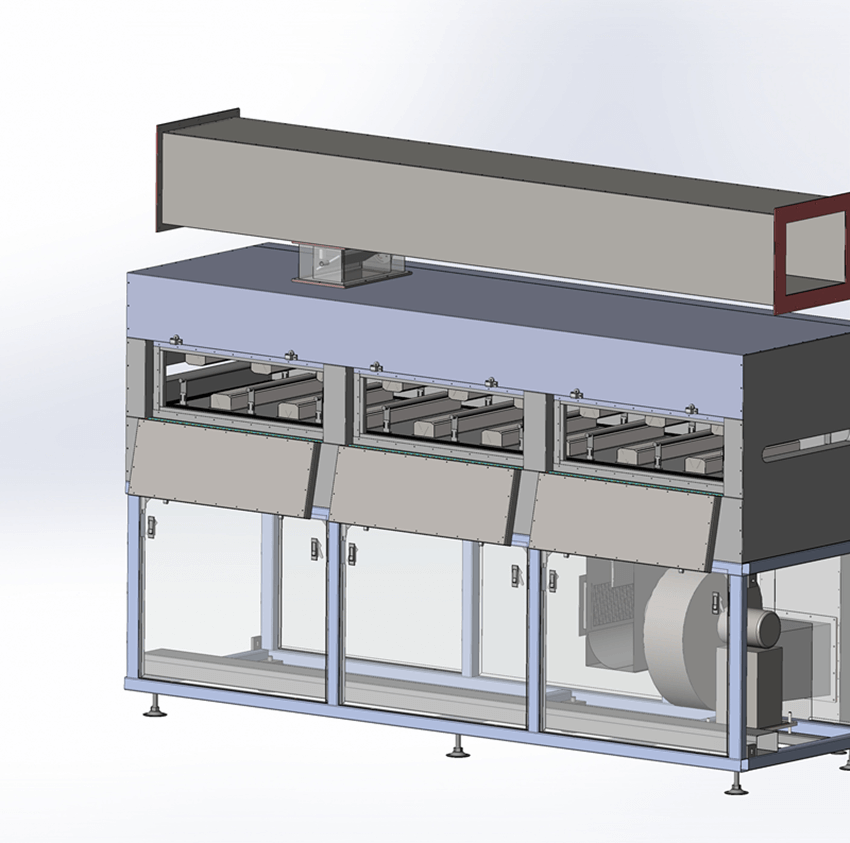

3. Mécanisme de séchage (chauffage infrarouge + chauffage électrique du tube chauffant en acier inoxydable)

Dans la partie séchage, le ventilateur est contrôlé par le convertisseur de fréquence pour fournir de l'air au four, qui est chauffé par le radiateur électrique avant d'entrer dans le four. Et équipé d'une fonction de recyclage d'air chaud, réduisant efficacement le coût d'utilisation. Le convertisseur de fréquence étant utilisé pour contrôler le moteur d’alimentation en air, la régulation du volume d’air est pratique. Le ventilateur est en acier inoxydable et durable.

|

Structure du four |

Chauffage indépendant monocouche, disposition haut et bas, les deux premiers fours de chauffage adoptent le mode de chauffage du sac chauffant indépendant haut et bas, les deux seconds fours de chauffage adoptent le mode de chauffage du sac chauffant commun. |

|

2 premiers chauffages d'appoint |

La structure de chauffage auxiliaire infrarouge est adoptée pour éviter les fissures lors du processus de chauffage et accélérer la vitesse de séchage. |

|

Longueur du four |

12m (3m/tronçon, 4 tronçons au total) |

|

texture du matériau |

Acier inoxydable, norme nationale du conteneur interne SUS304 (1,0 mm), norme nationale du conteneur externe SUS201 (1,2 mm) |

|

Mode d'entraînement du rouleau de guidage du four |

Tous les rouleaux de guidage sont principalement entraînés par un servomoteur d'un diamètre de Φ 60 mm et une surface plaquée de chrome dur ; les premier et deuxième rouleaux de guidage sont en répartition en arc ascendant, les troisième et quatrième rouleaux de guidage sont en répartition en arc descendant avec une chute totale de 200 mm. |

|

Contrôle de la température |

Il est divisé en contrôle de température de fonctionnement normal et contrôle de protection de l'alarme de surveillance de surchauffe. Lorsque la température est dépassée, une alarme sonore et visuelle apparaîtra et l'alimentation principale du chauffage sera coupée ; chaque section est entièrement contrôlée indépendamment |

|

Mode chauffage |

Chauffage infrarouge + chauffage électrique à caloduc en acier inoxydable, structure de circulation d'air chaud |

|

Puissance de chauffage du four à section unique |

Avant 2 sections 22KW * 3M, arrière 2 sections 18kw * 3M |

|

Température au four |

Design Max150 â, différence de température dans le four à une seule section ⤠5 â |

|

Température de surface du boîtier pendant le fonctionnement |

â¤45â |

|

Méthode de soufflage |

Soufflage d'air supérieur et inférieur, le volume d'air supérieur et inférieur est respectivement contrôlé par la vanne, qui peut être ajustée avec précision ; les chambres à air supérieure et inférieure partagent le corps de chauffe |

|

Contrôle du volume d'air extrait de chaque section |

Par vanne mécanique, contrôle indépendant, réglage fin |

|

Structure de la buse |

La direction de soufflage est de 30 degrés par rapport à l'horizontale et la rainure de la buse d'air est fendue avec un moule spécial |

|

Contrôle du ventilateur |

Contrôle du contacteur CA |

|

Contrôle du chauffage |

Relais statique |

|

Matériel d'éventail |

Acier inoxydable SUS304 selon la norme nationale |

|

Capacité de soufflage de chaque section (3m) |

4500m3/h, pression : 550pa à vitesse nominale |

|

Volume d'échappement (deux au total) |

10000m3/h, pression : 600Pa à vitesse nominale |

|

Système de récupération de solvant |

Non, uniquement l'installation de l'interface |

|

Alarme de concentration de solvant NMP |

Aucun (cette fonction doit être citée séparément) |

|

Surveillance de la pression de la chambre à air |

Aucun (cette fonction doit être citée séparément) |

|

Volume d'air évacué |

100-350 m3/min |

1 Emballage standard exporté : protection anticollision interne, emballage externe en boîte en bois pour l'exportation.

2 Expédition par express, par avion, par mer selon les exigences des clients pour trouver le moyen le plus approprié.

3 Responsable des dommages pendant le processus d'expédition, changera gratuitement la pièce endommagée pour vous.

Précédent :

Machine de soudage laser pour le soudage de plaques de couverture supérieure de batterie prismatiqueSuivant :

Machine d'empilage automatique de haute précision pour la fabrication de cellules prismatiquesCatégories

Nouveaux produits

boîte à gants sous vide en acier inoxydable h2o & O2 système de purification En savoir plus

Broyeur à boulets planétaire pour le broyage de poudre En savoir plus

Lab 12t Presse hydraulique manuelle avec une jauge de pression numérique optionnelle couramment utilisée dans les laboratoires infrarouges En savoir plus

© Droit d\'auteur: 2026 Xiamen Tmax Battery Equipments Limited Tous droits réservés.

IPv6 réseau pris en charge