Rejoindre TMAX, devenir agent!

Rejoindre TMAX, devenir agent!

Sales Manager:David

Email:David@tmaxcn.com

Wechat:18659217588

Numéro d\'article.:

TMAX-YK-XG5010Paiement:

L/C, T/T, Western Union, Credit Cards, PaypalOrigine du produit:

ChinaPort d\'expédition:

Xiamen PortDélai de mise en œuvre:

5 Dayscertificat :

CE, IOS, ROHS, SGS, UL Certificategarantie :

Two years limited warranty with lifetime technical support

â ãIntroduction à l'équipement ï¼

1.1 Domaine d'applicationaï¼

L'équipement est principalement utilisé pour l'observation des défauts internes des produits dans l'industrie des batteries, la production de pièces semi-conductrices, le traitement de produits électroniques, les substrats solides, l'emballage de produits électroniques, l'alimentation électrique et d'autres industries.

1.2 Introduction aux fonctions et principes de l'équipementï¼

L'équipement émet des rayons X via le générateur de rayons X et pénètre à l'intérieur de l'objet testé. L'intensificateur d'image reçoit les rayons X et prend des images et des photographies. Les défauts de l'objet testé sont déterminés manuellement en fonction des images.

â¡ãParamètres principaux :

|

Article |

Détails |

|

RAYONS X Tension |

Maximum 90 kV |

|

RAYONS X Actuel |

Max 200uA (valeur limite du logiciel:Max:89uAï¼ |

|

Période de garantie du tube à rayons X |

Durée de garantie accumuléeâ¥6000h |

|

Intensificateur d'image |

Intensificateur d'image 4" |

|

Résolution du système d'imagerie |

75/110 lp/cm |

|

Période de garantie du booster |

Durée de garantie accumuléeâ¥6000h |

|

Nombre de systèmes d'imagerie |

1ensemble |

|

X-CCD |

â¥1,3 millions de pixels |

|

Répéter la précision du test |

±0,06 mm (mesure de feuille standardï¼ |

|

Taux d'utilisation des équipements |

â¥98% |

|

Taille de la scène |

510mm X 460mm |

|

Plage de détection efficace |

450mmX410mm |

|

X Fuite de rayonnement |

â¤1,0 μSV/hï¼Un testeur de dose de rayonnement certifié par un tiers doit être utiliséï¼ |

|

Configuration de l'ordinateur |

Advantech, processeur i5, mémoire 4 Go, disque dur de 1 To, écran 21,5 pouces |

|

Méthode de détection : |

Mode de mesure hors ligne, navigation automatique, observation manuelle et jugement manuel |

â¢ãDescription des composants de l'équipementï¼

3.1 Générateur de rayons X à micro-foyer et système de contrôle ;ï¼

3.2 Système d'imagerie de détection à rayons X ;

3.3 Boîtier de protection contre les rayons X ;

3.4 Système de commande électrique ;

3.5 Contrôler le PC et le traitement des images ;

3.6 Dispositif de protection contre la mise hors tension automatique ;

3.7 Rappel de l'état de l'équipement d'éclairage à trois couleurs ;

3,8 Dispositif de commande par induction photoélectrique ;

3.9 La plaque métallique et la fenêtre en perspective de l'ensemble de la machine sont recouvertes d'une plaque de plomb pour garantir la sécurité contre les radiations et empêcher les fuites de radiations ;

3.10 Appareil de navigation ;

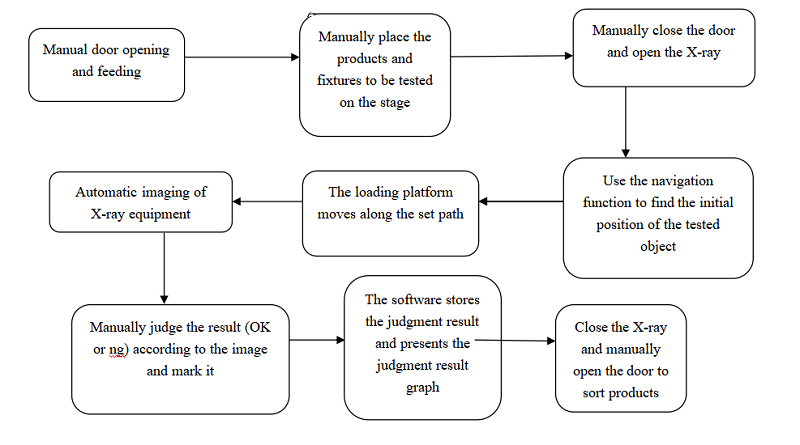

â£ãExigences du processus de fonctionnement du processusï¼

â¤ãConfiguration générale et standard d'équipementï¼

5.1 Couleur d'aspect de l'équipement : gris chaud 1C (ou selon plaque couleur du client).

5.2 Mesuré à 1 m de l'équipement (position de fonctionnement), le bruit de l'équipement est de ≤ 75 dB.

5.3 L'équipement est conforme aux normes de sécurité de la Chine pour les équipements électromécaniques.

5.4 Tailleï¼L1200mmÃW 1100mmÃH1830mmï¼Le la taille spécifique doit être soumise à l'objet réelï¼

5,5 Poids total : 760 KG

5,6 Atempérature ambianteï¼25±3â

5,7 Humidité ambiante : ⤠60 % RH (sans condensation)

5,8 Puissanceï¼2,5 KW

1 emballage standard exporté : protection anticollision interne, emballage de boîte en bois d'exportation externe.

2 Expédition par express, par avion, par mer selon les exigences des clients pour trouver le moyen le plus approprié.

3 Responsable des dommages pendant le processus d'expédition, changera gratuitement la pièce endommagée pour vous.

Précédent :

Machine de tri et de test automatique pour les tests de résistance interne et de tension de batterie prismatiqueSuivant :

Machine de soudage laser automatique 1500W pour le soudage prismatique des boîtiers et des capuchons de batterieCatégories

Nouveaux produits

boîte à gants sous vide en acier inoxydable h2o & O2 système de purification En savoir plus

Broyeur à boulets planétaire pour le broyage de poudre En savoir plus

Lab 12t Presse hydraulique manuelle avec une jauge de pression numérique optionnelle couramment utilisée dans les laboratoires infrarouges En savoir plus

© Droit d\'auteur: 2026 Xiamen Tmax Battery Equipments Limited Tous droits réservés.

IPv6 réseau pris en charge